Some Assembly Required

When manufacturers show these machines on their websites, they never seem to show all the ancillary components that are necessary for a fully functional machine. These nice compact machines expand rapidly as the air blowers, water chillers and air filtration systems are added.

Installing the Laser Tube

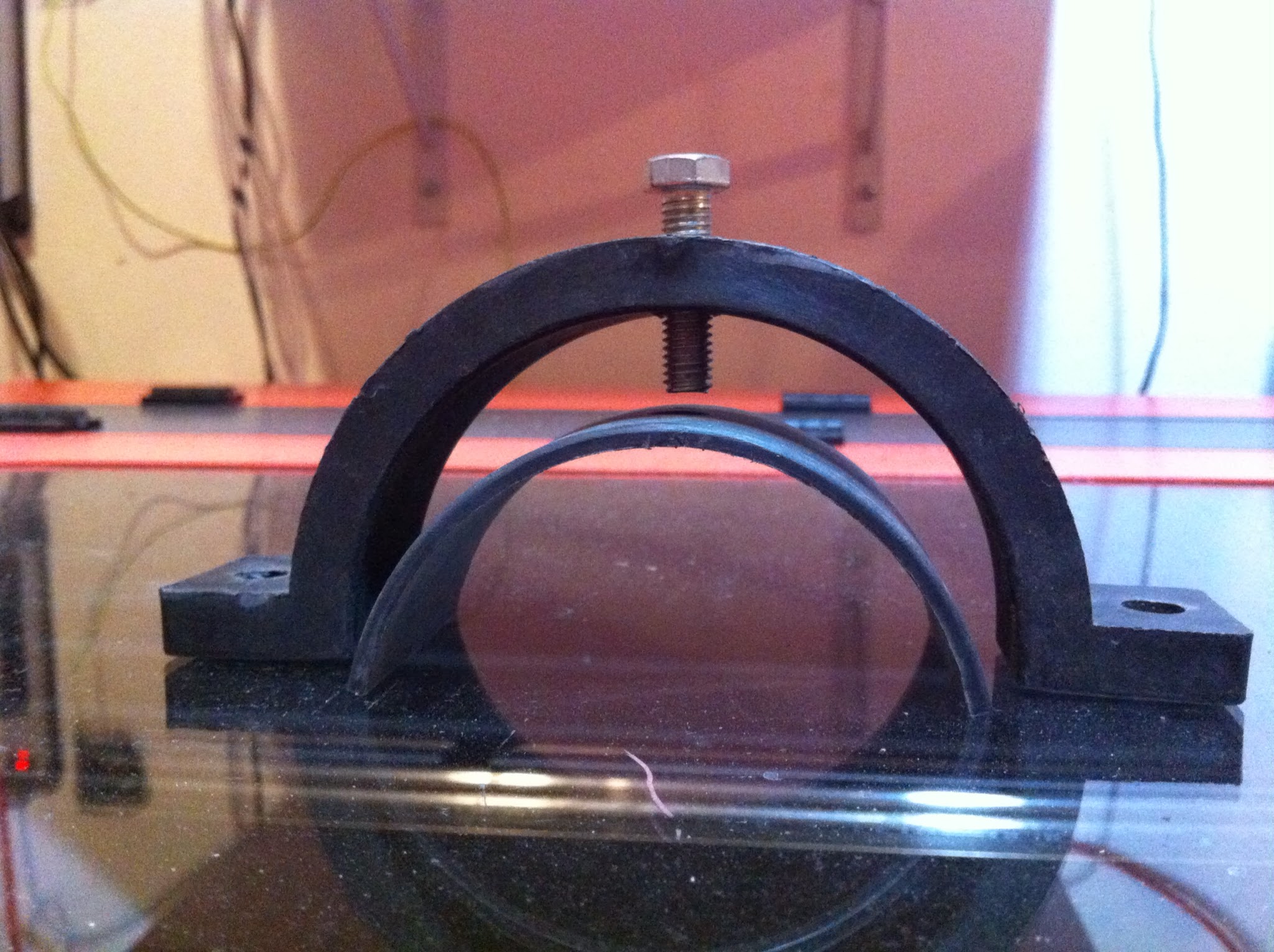

The laser tube mounts along the back side of the enclosure. It's covered by a long lid that protects it and keeps all that infrared radiation contained. There are some lower adjustable "yokes" for the tube to sit in and another "yoke" that clamps over the top of the tube with a long bolt that can be tightened down onto some plastic shims. Kind of an interesting looking setup, but we'll see how it works.

You can clearly see the plastic adjustment screw on the bottom yoke. There is one on each side to allow for adjustment both laterally and vertically.

The tube is longer than the enclosure so there is a hole in the side where the end of the tube sticks out, and an extra cover that bolts on to protect it. Another one of those things they don't show on the product webpage.

The high voltage wiring is attached in a strange way. There are two little protruding leads coming out of the tube, and the instructions say to simply wrap the wire around them and put silicone over them. I'm not sure about the longevity of that solution but time will tell.

Venting

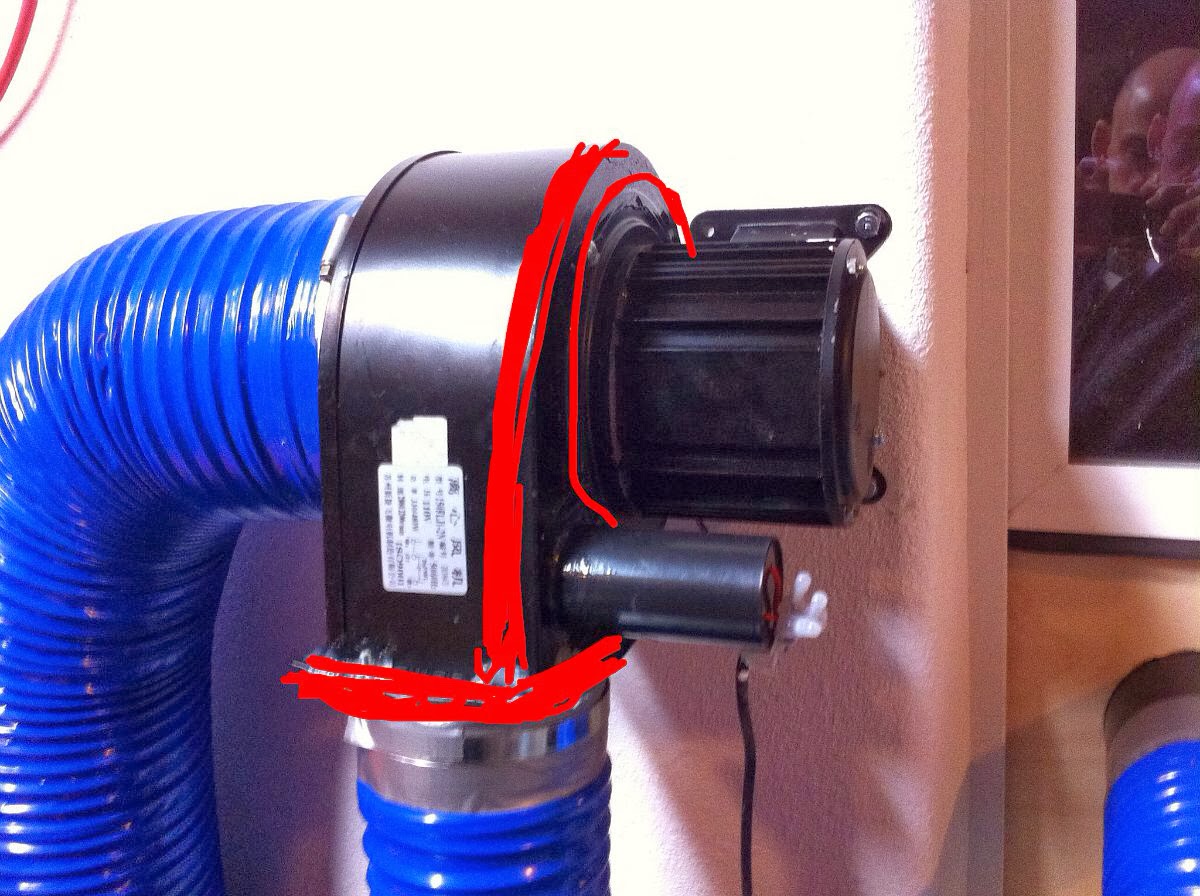

The ventilation system consists of a blower motor with a 6" inlet and 4" outlet, along with some blue plastic flex duct. We bolted the blower to the wall next to the window and made a vent with a damper to blow the air outside.

The first issue with the blower was that it leaked, a lot. Here's a picture showing in red all the places where air was blowing freely. The thickness of the line represents the amount of airflow. Thicker lines == more leaking.

So, yeah. Anywhere two pieces of metal were connected together there was a leak. I tried sealing up all the cracks with caulk, but I couldn't get rid of all leaks. Not super helpful when trying to remove nasty smelling bits of vaporized material. We're going to need an air filter of some sort to fix that.

Water Chiller and Air Pump

We mounted a shelf up on the wall above where the machine would sit so we could put the water chiller and air pump up off the ground. The water chiller is pretty hefty and holds about three gallons of distiller water. Its purpose is to pump water through the laser tube and take away the heat produced by the laser.

It makes a couple ear piercing beeps when first turned on, followed by a steady hum as the pump does its thing. There is a flow meter inside the laser enclosure which won't allow the laser to fire unless there is water flowing through the tube. Nice feature. The air pump is used to blow a stream of air through the tip of focus lens housing to keep particles off the lens and probably to blow out any small flash fires that might pop up.

Fire Extinguisher

Get one!! The laser is a death ray of heat vaporizing material as it passes, so a fire extinguisher is an absolute must. I found a pretty inexpensive halotron extinguisher on Amazon.com that doesn't leave any powdery reside when it's used.

All Together Now

Getting closer to being able to actually burn something! Next up is the laser alignment.